Design Tools

Buildings do not just have to be protected against rain, snow and temperature fluctuations, but also against the wind.

Effect of wind on flat roofs

A critical performance characteristic of a roof is its ability to withstand the environment in which it is installed. Depending on the building’s location and geometry, the wind pressures acting on the roof surface can be extremely high and turbulent. Therefore it is important to ensure that the roof system is secured to withstand these forces. Protan’s wind load calculation enables a roof’s requirements to be designed according to the latest European standards (EN 1991-1-4) using high quality, tested and approved fasteners.

Negative pressure

Wind causes negative pressure over flat roofs owing to the difference between static and dynamic pressure. In the case of hurricane-force winds, the negative pressure could be several hundred kilograms per m2, and is strongest at the corners and edges of the roof surface. In the case of turbulence, the roof structure is exposed to suction from above, in addition to which there is often pressure from inside as a result of leaks in the building's wall and roof structures.

Wind load calculation

By combining the choice of Protan’s various roof systems and different fastener options, Protan can optimise both the membrane usage and quantities of fasteners required for the roof system, whilst maintaining a technically superior solution.

Please contact us for more information or for wind load calculation.

Protan Elmark, Configure a hall

Protan has been creating technical textile structures since 1939.We can manufacture the structure that is customised to your specific needs.

ProKalk is a key tool developed and used by Protan to provide the required documentation to the roofing contractor and client at the start of a project. It not only provides accurate project specifications, but it is also key to making precise offers.

ProKalk is a key tool used by Protan to provide the required documentation to the roofing contractor and client at the start of a project. The system is based on Norwegian Standard NS3420 and enables precise project descriptions and offers to be created with ease.

For the roofing contractor, ProKalk is not only an essential tool to provide accurate project specifications according to NS3420, but also key to making precise offers. ProKalk utilises Protan’s tariff system and experience to produce detailed material lists and work procedures enabling accurate pricing for offers and the creation of time schedules. Additionally, ProKalk can use the data created by ProPlan to calculate and create specifications based on architects’ drawings to the exact material quantities required. This eliminates guess work and over- or underestimating during the bidding process.

You also benefit from ProKalk with consistent and precise specifications and bidding documents. The system is kept up-to-date with the latest developments in NS3420 and can create multiple documents required at a project’s offer stage. Specifications created by ProKalk are detailed and thorough providing clarity and reassurance to you.

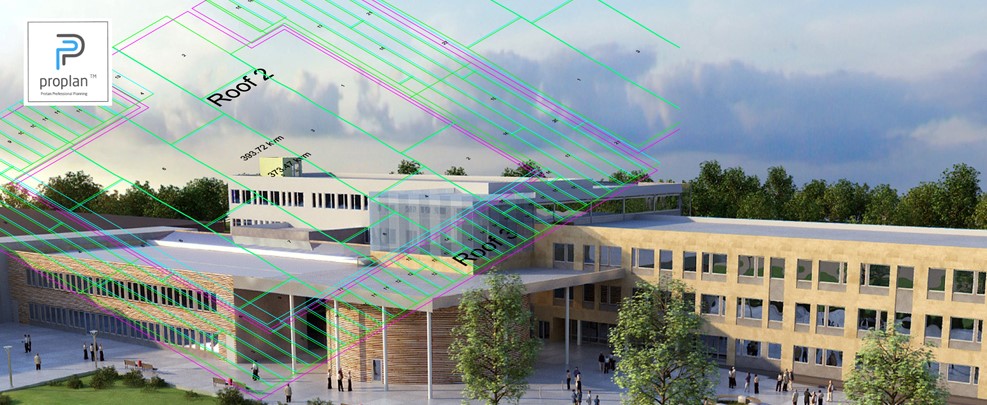

ProPlan is roof planning software that quickly identifies the best roofing solution for your project.

ProPlan is centred on a unique software tool developed by Protan. It specifies what is needed in the way of materials, installation solution, square metres, insulation, fasteners and accessories. It allows easy comparison of different Protan Roofing Systems, for example large prefabricated sheets or made-to-measure rolls. Additionally, ProPlan enables calculation of tapered insulation schemes using different manufacturers’ products to optimise the design to meet the desired U values and essential fire requirements.

ProPlan visualises the construction in 3D before converting it into a detailed specification, quotation and subsequent manufacturing and site assembly details. Benefits include substantial on-site installation and logistic savings and minimising waste.

Benefits

ProPlan offers many benefits to the specifier, contractor and building owner:

Reduction

- In installation costs

- In waste - the membrane is made to measure

- In logistical costs - the membrane is made to order not made for stock

Saving

- In completion time - allows internal trades to start earlier

- In process efficiency - using a single information platform

.png)

Building information modelling (BIM) is a process of creating three-dimensional intelligent constructions which provide architecture, engineering and construction professionals the information and tools to design, construct and manage buildings.

Protan has a wide portfolio of roofing products which in turn can be used in systems of many different designs.

We have created 13 BIM products/solutions to cover the majority of roofing constructions:

.png)

The objects can be found at www.bimobject.com/protan

More about BIM:

The concept of BIM has existed since the 1970s, but only with recent technology and software has it become a strategic focus for the construction industry. BIM allows for more collaboration between the different industries involved in building design and construction. The main goal is to save time and costs whilst reducing errors and the need to rework.

.png)

Governments are also increasingly pushing the use of BIM in order to increase productivity and reduce costs. Many state/government projects are now requiring the use of BIM.

Governments are also increasingly pushing the use of BIM in order to increase productivity and reduce costs. Many state/government projects are now requiring the use of BIM.

BIM is primarily used by architects, specifiers and engineers involved with the design and construction of buildings. The information in BIM is further utilised by facilities management for the maintenance of a building and ultimately used during the demolition.

A short video of how to use Protan objects in BIM projects can be found below:

:

For roofing contractors, we have created a brochure and an FAQ document with more information about how Protan utilises BIM.

This is BIM: Read our brochure

(Click to read)

BIM: Frequently Asked Questions

(Click to read)

The Protan Standard Overlap System with mechanical fastening can be installed on all types of substrate, and used on both new build and renovation projects.

.png)

For all types of substrate

The membrane is fastened to the substrate along the longitudinal sheet edges and overlapped by the adjoining roll. The two rolls are welded together using hot air. The material is fused homogeneously together at the overlap, so the joint is at least as strong as the roof covering itself. This is the system most commonly used for exposed roofs.

Protan SE and EX are the membranes used for mechanically fastened applications.

.png)

Protan standard overlap system

- rapid safe installation

- fast installation process

- can be installed in any weather

- suited to harsh climates

- strong joints

.png)

Protan Prefabricated Sheets system is the best and fastest solution in wind-exposed areas, so it is ideal when the roof has to be covered quickly.

.png)

Fast weather-tight roofing

The membrane is provided in 2 or 4 metre widths with high strength strips welded longitudinally on the underside for mechanical fastening. The system is a fast and efficient way of covering large, wind-exposed roofs. It has been developed to simplify installation and reduce installation time on site compared with the Standard Overlap System. The strips welded to the underside of the sheets can be tailored to even the toughest wind conditions.

Protan Prefabricated Sheets provide an optimum roofing system that can be engineered for an individual building. The strips on the underside of the membrane are welded at the factory. The strip spacing can vary depending on how exposed to wind the building is and how close the fasteners need to be. Protan Prefabricated Sheets are particularly suited to areas with strong wind forces.

Large areas of roof can be covered quickly with minimal welding work on site. The sheets make fast installation possible, as large sections of membrane are laid at a time, substantially reducing the amount of welding.

Protan prefabricated sheets

- rapid, safe installation

- fast building process

- suited to harsh climates

- weather independent

- fewer joints

See our video about Protan prefabricated sheets.

.png)

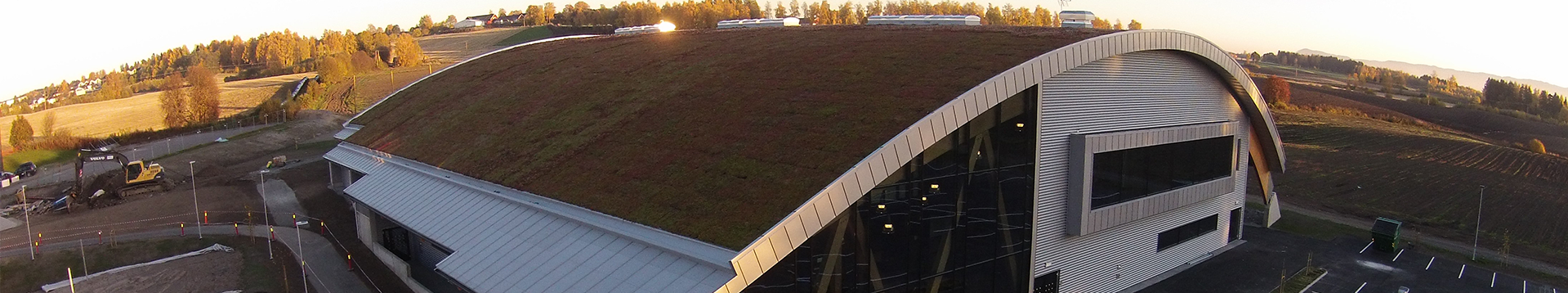

Protan Vacuum Roofing is a unique system that does not require fasteners or adhesives to be used on the roof surface. The wind forces create a vacuum effect that sucks the membrane firmly onto the roof structure. The windier it is, the better the system works.

.png)

The stronger wind, the better

When the vacuum roof is exposed to wind forces, negative pressure is generated in the layer between the membrane and an airtight, load-bearing substrate. This makes our vacuum roofing ideal in harsh climates. No fasteners need to be used on the roof surface, so the vapour control layer is not punctured. The membrane is laid in 2 or 4 metre widths, then air sealed against the parapet and around any penetrations.

Rapid installation

Protan Vacuum Roof System guarantees rapid installation and a speedy building process. The solution has very few joints and is a perfect match for projects with strict air tightness requirements, such as passive houses. Our vacuum roofing system is also ideal for buildings with high humidity, such as swimming pools, breweries, etc. If moisture is trapped in the roof structure, the vacuum system helps to vent it.

Protan Vacuum roof system

- unique solution

- rapid installation

- no fasteners or adhesives

- ideal in harsh climates

No noise during installation

Drilling noise can be a problem when renovating roofs. Fitting a Protan Vacuum Roof System reduces installation noise significantly, a major benefit for users of buildings such as offices, hospitals, schools and other institutions.

This is how it works

Protan’s vacuum system is based on the principle of anchoring the membrane by creating negative pressure in the layer between the membrane and the airtight substrate when exposed to wind loading. The negative pressure causes the membrane to be held down against the substrate, and the load is transferred downwards to the underlying supporting structure. The stronger the wind, the better the system works. The Protan vacuum system has been verified and approved by the Sintef Building and Research Institute (TG 2281).

Depending on the substrate, the following membranes are used: Protan SE or EX

.png)

Here you can view our video focusing on hand and machine welding.

Protan has developed several videos showing our installation methods and unique solutions for roofing and membranes. See the videos today for inspiration!

Protan’s PVC membranes are welded together using hot air. The quality of the welds need to be high to be able to withstand stresses as a result of wind forces and to be completely watertight.

This video discusses the use of hand welding machines and automatic welders.

Here you can view our video focusing on peel testing.

Protan has developed several videos showing our installation methods and unique solutions for roofing and membranes. See the videos today for inspiration!

Protan’s PVC membranes are welded together using hot air. Peel tests are used to check the quality of welding between the membrane sheets. These tests must be performed at the start of welding and throughout the welding process to ensure the quality is maintained.

This video shows how a peel test is performed.

Here you can view our video focusing on Protan Parapet and Grip Steel Bar.

Protan has developed several videos showing our installation methods and unique solutions for roofing and membranes. See the videos today for inspiration!

Prefabricated parapet membrane combined with Protan Grip Steel Bar ensures a linear and effective installation on the areas of the roof most exposed to wind.

Here you can view our video focusing on Protan Pipe detail.

Protan has developed several videos showing our installation methods and unique solutions for roofing and membranes. See the videos today for inspiration!

Detailing penetrations on a roof is extremely important and whilst Protan provides a large range of prefabricated details, it is also important to be able to construct a detail by hand.

This video focusses on the construction of a pipe detail.

Here you can view our video focusing on Protan Box Gutter.

Protan has developed several videos showing our installation methods and unique solutions for roofing and membranes. See the videos today for inspiration!

Protan’s gutter solution takes advantage of prefabricated membranes providing a simple yet effective solution.

Here you can view our video focusing on Protan Metal Edge Flashing.

Protan has developed several videos showing our installation methods and unique solutions for roofing and membranes. See the videos today for inspiration!

Terminating a roof edge without a parapet requires the use of a metal edge flashing. This simple solution provides a robust and tidy finish to the roof edge.

.png)

.png)

.png)