What is Tunnel Membrane Application?

Tunnels are often flooded by groundwater for structural reasons. Many tunnels are faced with the inundation of ground waters, as they are completely located in the mountains or the games on the hills. Tunnels are characteristic structures and the water structure of the regions where they are built should also be considered. For this reason, waterproofing works can be done by applying different techniques in tunnels.

Tunnel membrane application should be done in subway, highway, train tunnels in case of water flow and water leakage that may be caused by rain. During tunnel insulation applications, the type, structure and other geological criteria of the tunnel are taken into consideration. Tunnels through rock only deal with seepage from cracks in the rock. In this case, there is no puddle and waterproofing is applied only on the rock. This is called partial waterproofing. In the case of tunnels in brittle or loose rocks, it is possible to encounter springs and waters flowing through the strata. In this case, the tunnel must be completely wrapped with waterproofing materials designed to withstand the expected hydraulic pressure.

What Does Tunnel Membrane Application Do?

It is extremely important both technologically and economically that underground structures are protected against water ingress. Tunnel waterproofing is also essential for safe operation and durability. When tunnels are built with long service lives, it is imperative that the tunnel construction standards, especially those covering sealing and waterproofing systems, are high.

What are Tunnel Membrane Application Materials?

Protane; It offers solutions for subway, tunnel, underground structures insulation, storage and concrete protection applications. It is possible to achieve high performance in tunnel and subway applications with Protan BA/T geomembranes.

How Are Tunnel Membrane Application Materials Used?

Oil and solvents can damage Protan BA/T geomembranes. Protan BA/T geomembranes should not come into contact with thermal insulation materials made of rigid polystyrene foam. In addition, a separating layer should be used in between when necessary.

What are the Types of Tunnel Membrane Application Materials?

PVC is formed with the help of appropriate and necessary additives and is a durable, weather-resistant and durable plastic alloy. A surface cleaning is not required before welding PVC membranes, which have an application history of approximately 40 years. PVC membranes melt during welding and solidify along the joint surface. In this way, it creates a very distinct and neat form. Thus, the quality controls of the joints can be made more easily, saving both time and labor. PVC membranes; It can be used in subway, railway and road tunnels.

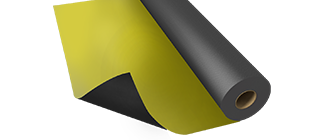

Protan BA/T geomembranes are produced from flexible polyvinylchloride, in other words PVC, with a light colored signal layer. Protan BA/T geomembranes can be used in all kinds of tunnel and subway applications. In addition, it is suitable to be used in the insulation of storage and concrete protection systems and underground structures. Protan BA/T PVC covers are produced for use in foundation bundling and waterproofing details of all types of structures.

Tunnel Membrane Application Materials Advantages

Protan BA/T geomembranes are homogeneous and resistant to plant roots. Protan BA/T geomembranes, which comply with TS EN 13967 standards, can be produced with wide roll sizes, allowing fast and economical application. Protan BA/T geomembranes, which draw attention with their dissolution and decay resistance, also contribute to ambient lighting thanks to the light reflections formed on their surfaces. In addition, possible damage to the membrane due to any mechanical reason during or after the application reveals the dark colored part on the substrate. Therefore, damage detection in Protan BA/T geomembranes is also easy. Protan BA/T geomembranes, which draw attention with their high quality, which is followed very closely by accredited production laboratories with independent test laboratories, are highly impermeable even in permanent deformations. Vapor-permeable Protan BA/T geomembranes are at the forefront with their high puncture strength and limited UV resistance. In addition, Protan BA/T geomembranes are extremely advantageous due to their recyclable nature-friendly material.